HEAT EXCHANGERS and COOLING SYSTEMS

GAS CONDITIONING TOWERS

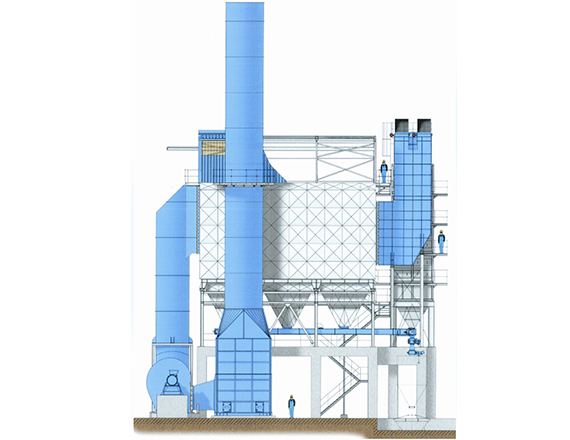

When performing exhaust gas cleaning, the exhaust gas needs to be cooled down prior to starting the cleaning process. Otherwise, the hot exhaust gases can damage and reduce the life of fabric filter bags in the dust collector. Cooling the exhaust gases in a gas conditioning tower can maximize uptime and decrease costly maintenance.

To cool the hot exhaust gas, very fine water droplets are injected into the gas conditioning tower, whereby the evaporation process withdraws heat and achieves the desired temperature for the subsequent exhaust gas cleaning.

To maximize operational safety, the water droplets are uniformly atomized and flow evenly through the evaporation section. Two-component compressed-air nozzles or one-component high-pressure nozzles are used in order to efficiently disperse the cooling water. Depending on the application, the exhaust gas flows vertically from the top down or from the bottom up.

GAS CONDITIONING TOWERS

Mass Coolers

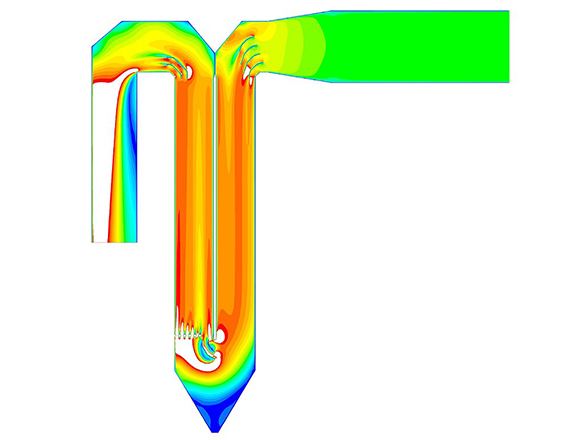

Where brief temperature fluctuations occur such as batch processes, air pollution control components work as thermal energy stores. Mass heat storage effect occurs when the heat transferred to the sheet metal walls cause the material to heat up.

Scheuch mass cooler harnesses this effect to balance exhaust gas temperatures. It can also serve as a spark separator. The sheet stacks incorporated into the mass coolers have been calculated to produce optimum thermal characteristics and reduce the sheeting volume to a minimum. Depending on the required cooling output, the design focuses on either free-standing coolers or individual mass cooler stacks in extraction lines.

GAS CONDITIONING TOWERS

Mixed Air/Fresh Air Cooling

Mixed air cooling is used when minor cooling is required occasionally, or in cases where cooler partial air flows are already available in the facility. The mixed air is drawn into the mixing section by temperature-controlled flaps or by axial fans. Structural costs are much lower compared to other cooling systems. However, since this increases the volumetric air flow, the air pollution control equipment must be larger in scale.

CONTACT US

SALES & SERVICE

Daniel Locke

1-260-226-1035

SPARE PARTS

James Reynolds

1-913-951-8586

TECHNICAL ENGINEERING

Martin Hermandinger

"*" indicates required fields