Industries

ENERGY

Integrated air pollution control system solutions in the Energy industry for all types of flue gas cleaning and waste heat utilization provide a competitive edge to our energy clients. Exceeding client expectations of high availability, increased efficiency through the implementation of flue gas condensers, as well as quality control and stringent adherence to emissions regulations is paramount to success.

Biomass

Natural biomass is the biodegradable component of organic agricultural and forestry wastes, with negligible contamination. This can include wood pellets, straw, sunflower husks, wood chips or corncobs. Depending on the fuel in question, different Scheuch products and combined systems are implemented. Through the addition of a flue gas condensation system, up to 50% of the rated boiler capacity can be recovered, depending on the fuel moisture content.

Waste Wood

The term waste wood encompasses all wood, which would either be disposed of conventionally or is designated as a fuel for combustion plants. There are many different classifications and they vary from country to country, but generally as the proportion of contaminants in the wood increases, the equipment required for the cleaning of the flue gases becomes more complex and comprehensive. Scheuch offers a variety of complete solutions for all classifications of waste wood.

Fossil Fuels

Fossil fuels like coal, peat and crude oil have developed by undergoing a slow biological and physical transformation from ancient plant-based biomass. During their combustion greenhouse gases, as well as other environmentally relevant pollutants, like dust, ash, and SO2, are released and must be separated and removed from the flue gas. This is yet another area, where Scheuch can offer customized flue gas cleaning solutions.

Waste

Refuse-derived fuels and other wastes contain contaminants which when combusted, release acidic pollutants like SOx , HCl, and HF, as well as organic and inorganic compounds like dioxins, furans, and heavy metals. Scheuch offers a variety of absorptive cleaning processes to comply with emissions regulations, while maintaining the highest possible availability. Due to our long-term experience in this sector, we can offer technologically mature solutions.

DUST FILTRATION

Process Filters

Scheuch’s innovative air pollution control (APC) technology have found their place in a variety of applications across the globe. Our global subsidiaries allow us to meet our client’s clean air requirements through every step of the manufacturing process. Product scope extends from baghouse dust collectors to exhaust gas cooling and waste heat utilization.

DUST FILTRATION

Nuisance Filters

Because of their large-volume valves and patented Impulse cleaning system, the Compact Impulse Filter model stands out with its low operating and maintenance costs. In addition, the compressed air cleaning system, the filter bag or cage design ensures the highest levels of operating reliability.

DUST FILTRATION

Hot-Gas Filter

Scheuch’s Hot-Gas Filter is the future of exhaust gas cleaning and dust control. This model can really take the heat. One of the many advantages is the high-temperature resistance of the ceramic (candle) filter elements. While conventional bag filters with fabric media reach their limits at process temperatures of 500° F (260° C), for hot-gas filters and their ceramic filter elements, even 932° F (500° C) is not a problem.

EXHAUST GAS CLEANING

Dry Sorption

Scheuch specializes in providing customized solutions for each individual application to ensure the best combination of low investment costs and minimal operating expenses. Scheuch dry sorption technologies include reducing acidic pollutants (HF, HCL, SOx) using additives based on Ca (calcium) or Na (sodium).

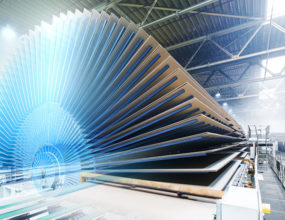

HEAT EXCHANGERS and COOLING SYSTEMS

Waste Heat Utilization

Waste heat utilization systems used with local heat and district heat allow the energy that is recovered to be put to the best possible use in a profitable way. Scheuch developed the Energy Recovery & Cleaning System (ERCS) that maximizes waste heat utilization for boiler outputs of up to 200 MW using condensers and economizers.

HEAT EXCHANGERS and COOLING SYSTEMS

Gas Conditioning Tower

When performing exhaust gas cleaning, the exhaust gas needs to be cooled down prior to starting the cleaning process. Scheuch’s gas conditioning towers provide exceptional efficiency due to its optimal instrument-based design and layout combined with adapted controls.

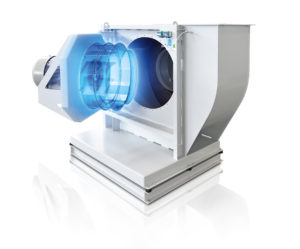

FANS

Radial Fans

Scheuch has built more than 70,000 industrial-grade radial fans to transport clean or exhaust air, chips, and fibrous material as well as explosive gas mixtures. Over the years, we have created and perfected a comprehensive program of roughly 1,700 fan types. These have pressure ranges from 750 Pa (4 in WC) to 30,000 Pa (80 in WC) and volume flows from 750 to 960,000 Am3/h (300 to 380,000 acfm).

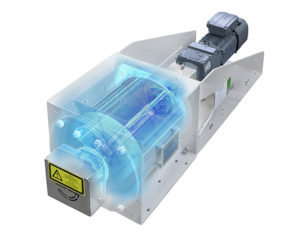

BULK MATERIAL HANDLING

Rotary Valves

Rotary valves are used to discharge dust, chipboard shavings, and fibrous conveyed goods. They can also be used as shut-off devices. Scheuch rotary valves can also be designed resistant to ignition and flame penetration for explosion decoupling purposes.

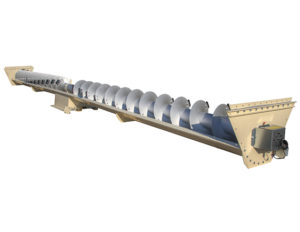

BULK MATERIAL HANDLING

Screw Conveyors

Tube and trough-type screw conveyors are used to continuously transport bulk materials at throughput volumes of 2 to 500 m3/h and with diameters between 8 and 40 inches (200 and 1,000 mm). Model types of screw conveyors include pipe, trough, and custom design.

BULK MATERIAL HANDLING

Pendulum Flaps

Pendulum flaps are used for the continuous dosing, blocking and discharging of bulk materials. The flexible structure of the Scheuch pendulum flaps enables reliable channeling and separation of free-flowing bulk materials out of and into pressure-difference chambers (e.g. filter systems). These are actuated pneumatically, electrically or mechanically.