INDUSTRIES

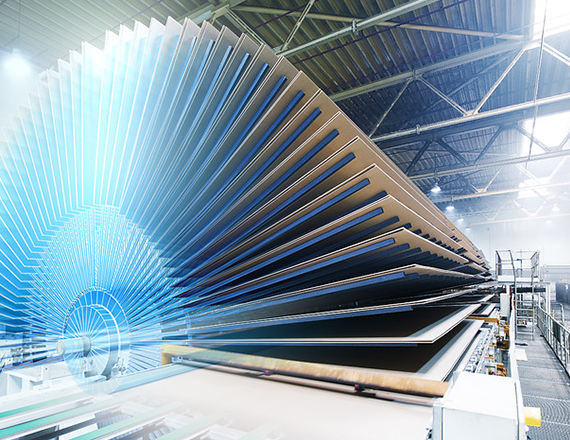

WOOD-BASED PANELS

Scheuch offers air pollution control solutions for dust control, exhaust air cleaning, pneumatic conveying, and fiber sifting for all production of wood-based panels industries such as particle board, MDF and OSB chipboard and fiber preparation. Scheuch meet these demands with our innovative technologies for the widest range of requests in dust collection and exhaust gas cleaning technology for the wood-based panels industry.

Fiber Sifting

In the final stage of processing before forming and pressing, the fiber sifting equipment has a great deal of influence on the safe production of high-grade board quality. With a degree of separation of up to 99%, the sifter provides the right conditions for a high level of availability for pressing. From the mixture of the ejection material from the sifter it is possible to recognize deviations from the upstream process steps safely and quickly. With early counteractive measures a high level of quality can be maintained and the proportion of A qualities can be increased.

Particle Board

Scheuch has two systems for detecting and cleaning exhaust air from continuous pressing of particle board, MDF and OSB production. The SAP process applies a preliminary cleaning of the exhaust gas before it is then fed through a longer pipeline for final treatment. The ESAP process meets the requirements with an integrated wet electrostatic precipitator module as a final cleaning system.

DUST FILTRATION

Process Filters

Scheuch’s innovative air pollution control (APC) technology have found their place in a variety of applications across the globe. Our global subsidiaries allow us to meet our client’s clean air requirements through every step of the manufacturing process. Product scope extends from baghouse dust collectors to exhaust gas cooling and waste heat utilization.

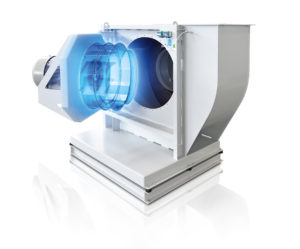

FANS

Radial Fans

Scheuch has built more than 70,000 industrial-grade radial fans to transport clean or exhaust air, chips, and fibrous material as well as explosive gas mixtures. Over the years, we have created and perfected a comprehensive program of roughly 1,700 fan types. These have pressure ranges from 750 Pa (4 in WC) to 30,000 Pa (80 in WC) and volume flows from 750 to 960,000 Am3/h (300 to 380,000 acfm).

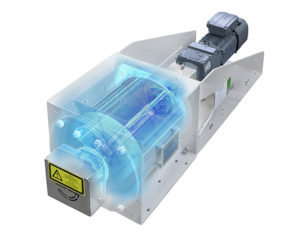

BULK MATERIAL HANDLING

Rotary Valves

Rotary valves are used to discharge dust, chipboard shavings, and fibrous conveyed goods. They can also be used as shut-off devices. Scheuch rotary valves can also be designed resistant to ignition and flame penetration for explosion decoupling purposes.

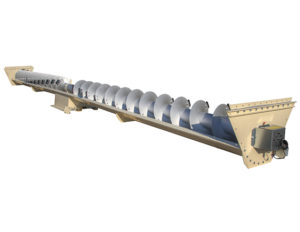

BULK MATERIAL HANDLING

Screw Conveyors

Tube and trough-type screw conveyors are used to continuously transport bulk materials at throughput volumes of 2 to 500 m3/h and with diameters between 8 and 40 inches (200 and 1,000 mm). Model types of screw conveyors include pipe, trough, and custom design.