APPLICATIONS

RADIAL FANS

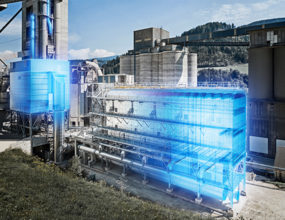

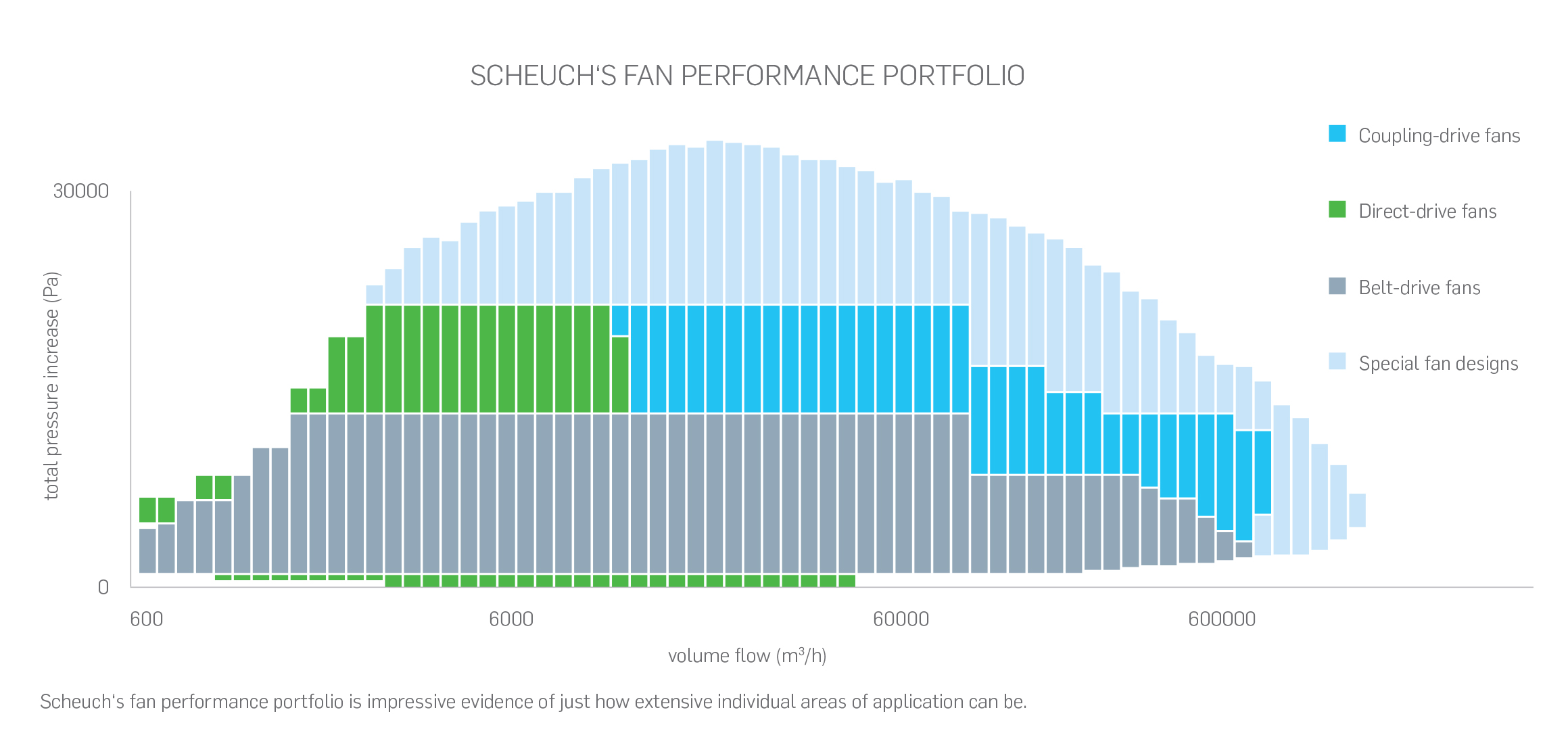

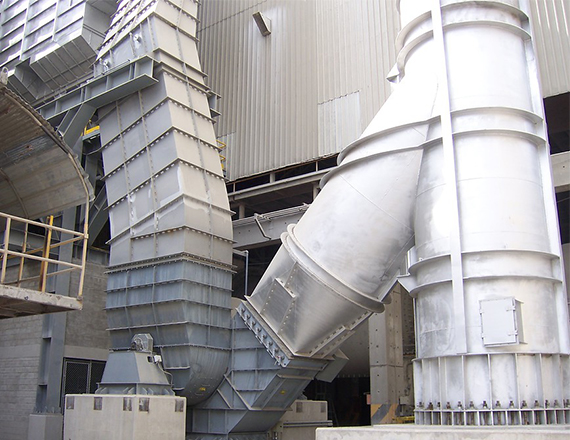

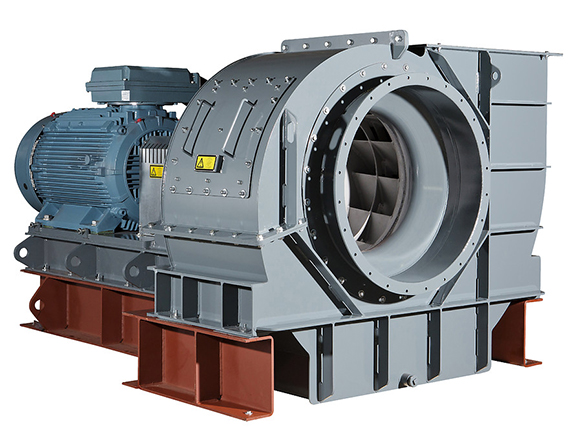

Scheuch has built more than 70,000 industrial-grade radial fans to transport clean or exhaust air, chips, and fibrous material as well as explosive gas mixtures. Over the years, we have created and perfected a comprehensive program of roughly 1,700 fan types. These have pressure ranges from 2″ WC (500 Pa) to 120″ WC (30,000 Pa) and volume flows from 300 to 600,000 acfm (500 to 1,000,000 m3/h).

Since these fans are used in particulate filtration and gas cleaning systems, Scheuch is well versed in a broad range of specific fan requirements for many different applications.

Selecting the right fan design has a significant impact on investment and operating costs. That’s why Scheuch fans are divided into a range of model types that take the relationship between the overall pressure increase and the volumetric flow into consideration for energy efficiency.

- Direct drive

- Belt drive

- Coupling drive

- Custom to application

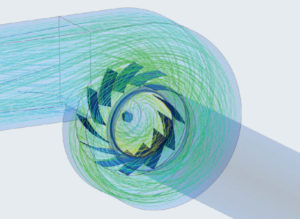

An optimized fan inflow has a significant influence on efficiency and energy consumption. With the help of computational fluid dynamics (CFD) simulations, we are able to optimize the inflow for installation situations where space is limited by performing calculations for a variety of baffle plate configurations.

RESEARCH & DEVELOPMENT

Research and development has always been the heart of Scheuch. Scheuch radial fans are designed using cutting-edge measurement technology to meet the highest of application requirements.

Scheuch radial fans achieve energy efficiency by boosting performance through flow optimization. An optimized fan inflow has a significant influence on efficiency and energy consumption. When it comes to planning, Scheuch consistently recognizes the importance of an efficient inflow and outflow. With the help of Computational Fluid Dynamics (CFD) simulations, we are able to optimize the inflow by performing calculations for a variety of baffle plate configurations such as where installation space is limited.

Scheuch Test Bench

- Every fan produced in Aurolzmünster, Austria (2,500 each year) are put on the test bench for half an hour before they are shipped. Vibrations and temperatures of the bearings are measured on each fan to ensure it will operate at its best.

- Scheuch uses a test bench for new developments such as bionic wheels, wear protection, and high temperatures to test different materials to maximize fan life.

- The test bench can run fans up to 1000 HP (750kW).

Proven Fan Engineering Expertise

- CFD simulations for optimizing flow technology

- Performance measurements on Scheuch’s own fan test bench (DIN EN ISO 5801)

- FEM calculations

- Sound analysis, expert assessments and proposed solutions

- Upgrades to increase performance and safety

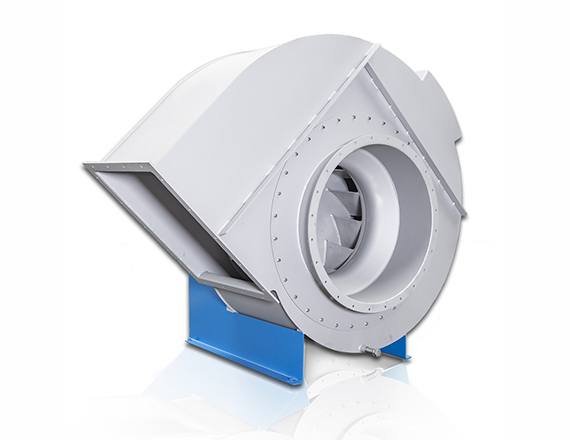

RADIAL FAN TYPES

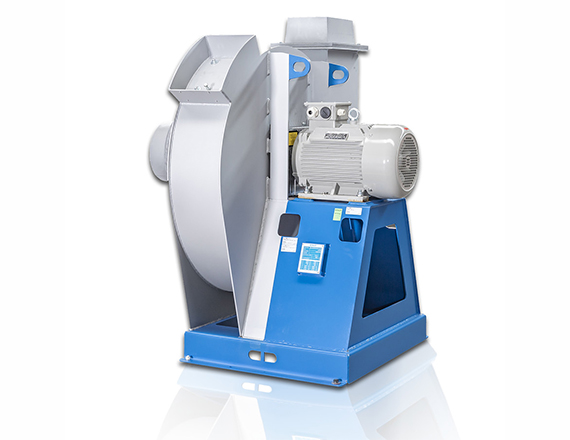

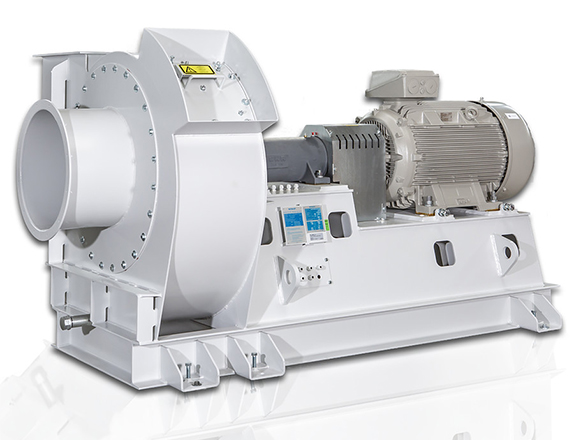

DIRECT DRIVE

Cleaning fans, especially the impellers often results in regular production down time. When this happens, every minute counts until the system can be put back into operation. To minimize down time, Scheuch developed the SwingOut and the PullOut direct-drive fan models. The impeller can be swung out to or pulled out from the housing without having to disconnect the duct from the fan. This makes cleaning the fan quick and easy that saves not only time, but money.

Specifications:

- Fan wheel is mounted to the motor shaft.

- Weight of the wheel is limited to the dimensions of the motor.

- 2-115” WG Static Pressure increase (710Pa up to 28.800Pa)

- Flows between 420 and 100,000 ACFM (710m³/h up to 168.000m³/h)

-

- Temperatures up to 2,200° F (1.200°C)

SwingOut Fans

Both the motor and impeller are installed on a single door so that the entire sub-assembly can be swung out to the rear. This makes the impeller easy to clean and to remove when necessary. Even larger fans with an impeller weight of several hundred pounds are available.

The SwingOut model is available with an impeller diameter up to 49″ (1,250 mm).

PullOut Fans

The PullOut fan is available for both direct drive and coupling drive. To make the fan easy to clean, the impeller is removed from the housing with the motor bracket and the motor itself.

RADIAL FAN TYPES

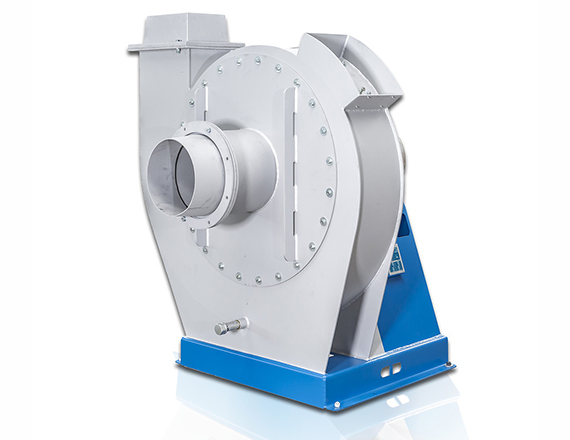

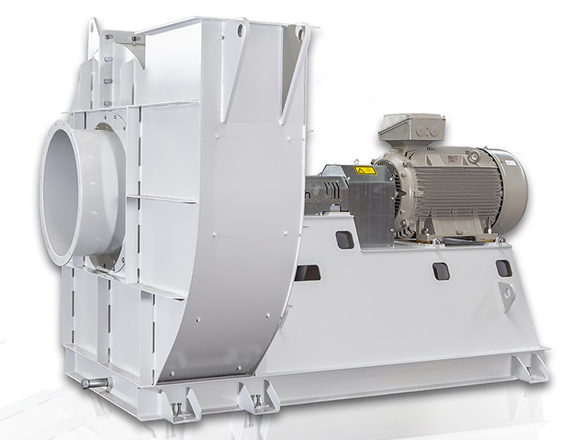

COUPLING DRIVE

Coupling drive fan wheel is mounted onto an extra shaft and the motor is connected by a coupling. If higher air volume is needed, Scheuch has large wheels that can be used.

Specifications:

- 2-115” WG Static Pressure increase (1.250Pa up to 28.800Pa)

- Flows between 420 and 445,000 ACFM (710m³/h up to 756.000m³/h)

- Temperatures up to 2,200° F (1.200°C)

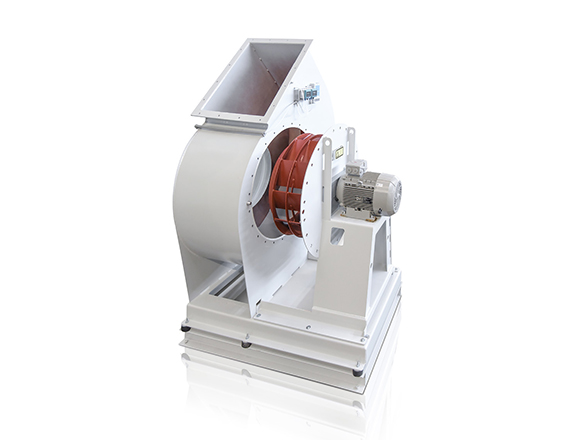

RADIAL FAN TYPES

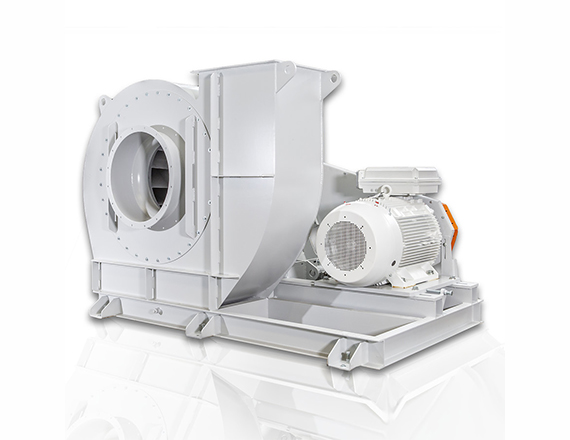

BELT DRIVE

Belt driven fans are used in rough environments. Before frequency converters were common to regulate the fan speed, the discs of the belt drive could be changed to also change the fan speed.

Specifications:

- 2-72” WG Static Pressure increase (1.250Pa up to 18.000Pa)

- Flows between 420 and 395,000 ACFM (710m³/h up to 672.000m³/h)

- Temperatures up to 2,200° F (1.200° C)

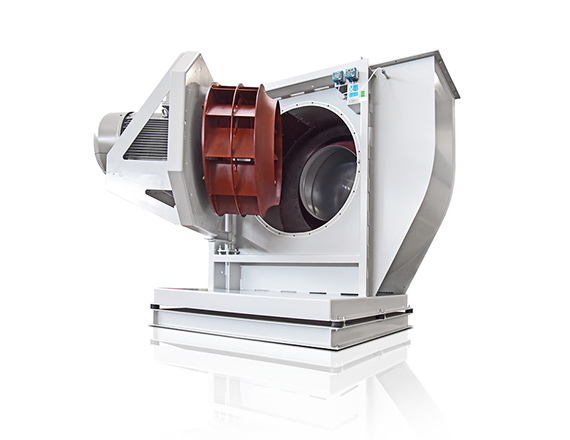

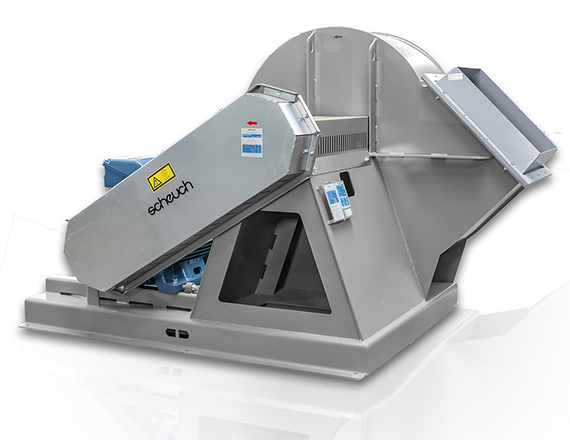

RADIAL FAN TYPES

CUSTOM

Countless systems the world over prove the unparalleled quality of Scheuch radial fans on a daily basis. For decades, Scheuch has been able to garner a wealth of technical process knowledge in a wide variety of industries. Our extensive and innovative range of radial fans can be customized to fit virtually any application.

- Transportation of explosive gas mixtures in 100% ppm-tight design for transporting hydrogen for example

- Pressure-shock-proof design

- Two-stage or multi-stage design for high-pressure levels

- Special materials for harsh environments such as stainless steel, aluminum

- Hot-gas applications up to 1022° F (550° C)

RADIAL FAN TYPES

ACCESSORIES

- Wear-protection designs

- Sound enclosures and silencers

- Control devices such as twist throttle, throttle flap, frequency converter

- Suction-side accessories like air intake chambers, joint adapters

- Electronic monitoring systems such as rotation, temperature and vibration monitoring

- Circulating oil lubrication

- Certifications: ATEX, TR ZU (EAC) certificate

CONTACT US

SALES & SERVICE

Daniel Locke

1-260-226-1035

SPARE PARTS

James Reynolds

1-913-951-8586

TECHNICAL ENGINEERING

Martin Hermandinger

"*" indicates required fields