DUST COLLECTION SOLUTIONS

NUISANCE FILTERS

Nuisance filters with large volume valves combined with the patented Impulse Dust Collection cleaning system, makes the Compact Impulse Filter model stand out with its low operating and maintenance costs. In addition, the compressed air cleaning system, the filter bag or cage design ensures the highest levels of operating reliability.

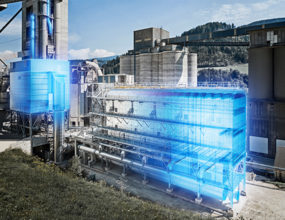

Compact Impulse Filter

The Scheuch Compact Impulse Filter is ideal for applications when capturing dust at the source is needed. The Compact Impulse Filter handles air volumes ranging from 118 to 11,771 acfm (200 to 20,000 m3/h). Compact Impulse Filter models are pre-assembled and delivered equipped with filter bags or cages with all pneumatic and electrical components ready for connection. Round filter bags or cages with a diameter of nearly 4 inches (100 mm) and the direct mounting of fans and exhaust silencers, allows this nuisance dust collector to operate with a higher air-to-cloth ratio. Because the Compact Impulse Filter uses the same components as in the large-scale Impulse Filters, customers can significantly reduce maintenance costs when operating multiple Impulse Filter models at their facility.

Cartridge Filter

Compared to filter versions with round tubes, cartridge filters offer three times the filter area with the same construction volume, reducing investment and operating costs. Cartridge filters are typically used as intake filters for central compressed-air systems and in bagging and packaging processes similar to what you will see in the plaster and dry mortar manufacturing industry.

Pipe cartridge filters are ideal when dedusting low volumetric flows 368 to 678 ft3/h (200 to 500 m3/h) with fine, free-flowing dry dusts in additive silos, bagging stations and manual dosers. The pressure shock-proof versions (10 bar) are the perfect solution for pre-hopper dedusting in pneumatic conveyor systems.

Safety filters with a cartridge filter design are used for protecting components connected downstream of a main filter (such as compressors). As a result, these units are also protected in the event that larger quantities of dust enter the clean gas stream in the main filter because of damage to the tube.

CONTACT US

SALES & SERVICE

Daniel Locke

1-260-226-1035

SPARE PARTS

James Reynolds

1-913-951-8586

TECHNICAL ENGINEERING

Martin Hermandinger

"*" indicates required fields